PLC

PLC

GE Fanuc IC693CMM321-DE Ethernet ControllerTestedwith RJ45 adapter

GE Fanuc IC693CPU341K CPU341 FW 5.00 Build 0 PLCcomm.Tested

GE Fanuc IC693MDL740E Output 12/24VDC 0.5A 16PT Positive

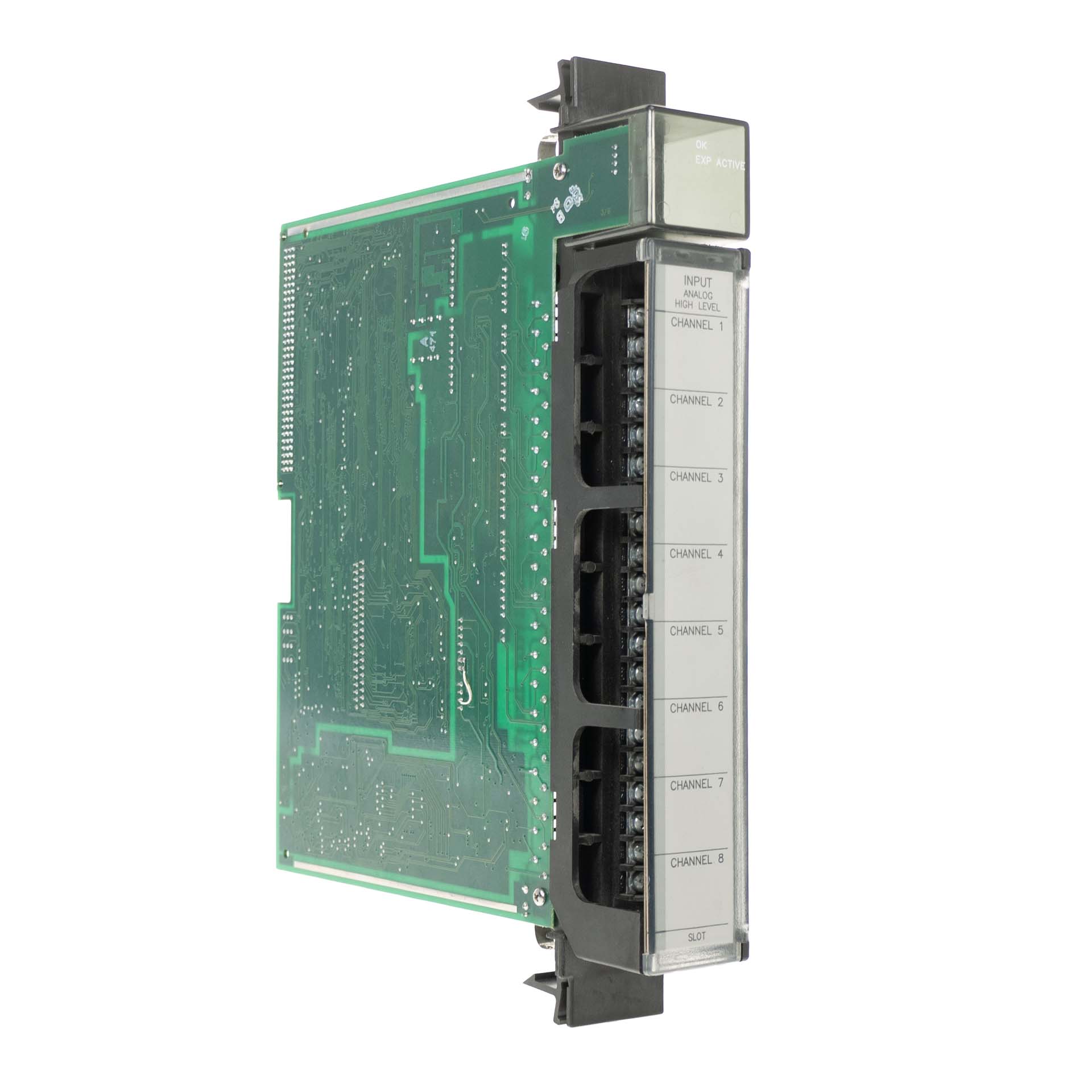

GE Fanuc IC697ALG440 IC697ALG440D Analog (I) Expander Module

GE Fanuc IC697BEM711C Bus Expansion Receiver The IC697BEM711 is a Bus Expansion Receiver module for the GE Fanuc Series 90-70 PLC platform. Its function is to logically extend the PLC's backplane, enabling a remote or expansion rack to function as an integral part of the main system. It operates as one half of a transmitter/receiver pair to create a single, contiguous backplane across multiple chassis. Core Functionality System Expansion: Allows a Series 90-70 PLC system to be expanded beyond a single rack. The CPU in the main rack can seamlessly address modules in the expansion rack as if they were local. Receiver Role: Acts as the dedicated receiver in the expansion link. It must be paired with a corresponding Bus Expansion Transmitter module (e.g., IC697BEM701) located in the main PLC rack. High-Speed Parallel Link: Extends the VME backplane's high-speed parallel bus over a dedicated bus expansion cable, ensuring minimal latency between racks. Transparent Operation: The bus extension is transparent to the CPU and other modules in the system. No special programming or communication logic is required to access modules in the expansion rack. Technical Specifications Module Type: Bus Expansion Receiver Platform: GE Fanuc Series 90-70 Backplane Requirement: Installs in any VME standard IC697 chassis. Power Consumption: 1.5 Amps @ +5 VDC Bus Cable Interface: Multi-pin D-sub connector for the bus expansion cable. LED Status Indicators: Front-panel LEDs provide status for Module OK and Bus Active, allowing for visual diagnosis of the expansion link's integrity. System Architecture and Use Case The IC697BEM711 is exclusively used in multi-rack Series 90-70 configurations where the total number of required modules exceeds the capacity of a single rack. A typical system consists of: A Main Rack containing the CPU and a Bus Expansion Transmitter module. A dedicated Bus Expansion Cable connecting the two modules. An Expansion Rack containing the IC697BEM711 Receiver module, a power supply, and additional I/O or option modules. This configuration creates a larger logical system, essential for complex automation tasks requiring a high density of I/O or special-purpose modules.

GE Fanuc IC697BEM711J Bus Expansion Receiver The IC697BEM711 is a Bus Expansion Receiver module for the GE Fanuc Series 90-70 PLC platform. Its function is to logically extend the PLC's backplane, enabling a remote or expansion rack to function as an integral part of the main system. It operates as one half of a transmitter/receiver pair to create a single, contiguous backplane across multiple chassis. Core Functionality System Expansion: Allows a Series 90-70 PLC system to be expanded beyond a single rack. The CPU in the main rack can seamlessly address modules in the expansion rack as if they were local. Receiver Role: Acts as the dedicated receiver in the expansion link. It must be paired with a corresponding Bus Expansion Transmitter module (e.g., IC697BEM701) located in the main PLC rack. High-Speed Parallel Link: Extends the VME backplane's high-speed parallel bus over a dedicated bus expansion cable, ensuring minimal latency between racks. Transparent Operation: The bus extension is transparent to the CPU and other modules in the system. No special programming or communication logic is required to access modules in the expansion rack. Technical Specifications Module Type: Bus Expansion Receiver Platform: GE Fanuc Series 90-70 Backplane Requirement: Installs in any VME standard IC697 chassis. Power Consumption: 1.5 Amps @ +5 VDC Bus Cable Interface: Multi-pin D-sub connector for the bus expansion cable. LED Status Indicators: Front-panel LEDs provide status for Module OK and Bus Active, allowing for visual diagnosis of the expansion link's integrity. System Architecture and Use Case The IC697BEM711 is exclusively used in multi-rack Series 90-70 configurations where the total number of required modules exceeds the capacity of a single rack. A typical system consists of: A Main Rack containing the CPU and a Bus Expansion Transmitter module. A dedicated Bus Expansion Cable connecting the two modules. An Expansion Rack containing the IC697BEM711 Receiver module, a power supply, and additional I/O or option modules. This configuration creates a larger logical system, essential for complex automation tasks requiring a high density of I/O or special-purpose modules.

GE Fanuc IC697BEM711M Bus Expansion Receiver The IC697BEM711 is a Bus Expansion Receiver module for the GE Fanuc Series 90-70 PLC platform. Its function is to logically extend the PLC's backplane, enabling a remote or expansion rack to function as an integral part of the main system. It operates as one half of a transmitter/receiver pair to create a single, contiguous backplane across multiple chassis. Core Functionality System Expansion: Allows a Series 90-70 PLC system to be expanded beyond a single rack. The CPU in the main rack can seamlessly address modules in the expansion rack as if they were local. Receiver Role: Acts as the dedicated receiver in the expansion link. It must be paired with a corresponding Bus Expansion Transmitter module (e.g., IC697BEM701) located in the main PLC rack. High-Speed Parallel Link: Extends the VME backplane's high-speed parallel bus over a dedicated bus expansion cable, ensuring minimal latency between racks. Transparent Operation: The bus extension is transparent to the CPU and other modules in the system. No special programming or communication logic is required to access modules in the expansion rack. Technical Specifications Module Type: Bus Expansion Receiver Platform: GE Fanuc Series 90-70 Backplane Requirement: Installs in any VME standard IC697 chassis. Power Consumption: 1.5 Amps @ +5 VDC Bus Cable Interface: Multi-pin D-sub connector for the bus expansion cable. LED Status Indicators: Front-panel LEDs provide status for Module OK and Bus Active, allowing for visual diagnosis of the expansion link's integrity. System Architecture and Use Case The IC697BEM711 is exclusively used in multi-rack Series 90-70 configurations where the total number of required modules exceeds the capacity of a single rack. A typical system consists of: A Main Rack containing the CPU and a Bus Expansion Transmitter module. A dedicated Bus Expansion Cable connecting the two modules. An Expansion Rack containing the IC697BEM711 Receiver module, a power supply, and additional I/O or option modules. This configuration creates a larger logical system, essential for complex automation tasks requiring a high density of I/O or special-purpose modules.

GE Fanuc IC697BEM713F - Genius Bus Transmitter Module Overview The GE Fanuc IC697BEM713 is a high-performance Bus Transmitter Module (BTM) designed for the Series 90-70 Programmable Logic Controller (PLC) platform. Its primary function is to serve as an interface controller for extending the PLC's I/O capabilities over the robust and deterministic Genius I/O bus. This module enables the central CPU to communicate with remote I/O blocks, creating a distributed and scalable control system architecture. It occupies a single slot in an IC697 PLC rack and acts as the master controller for one or more Genius I/O serial buses, managing data exchange with up to 31 remote I/O devices per bus. Key Features Genius I/O Bus Control: Acts as the bus controller for the proprietary GE Genius I/O network, known for its high-speed and reliable communication. Distributed I/O Capability: Allows for the connection of remote I/O blocks up to 7,500 feet (2,286 meters) from the PLC rack, reducing wiring costs and complexity in large-scale applications. High-Speed Data Transfer: Supports multiple baud rates, including 153.6K (standard), 76.8K, and 38.4K, providing flexibility in network design. Advanced Diagnostics: Provides extensive on-board diagnostics for the module itself and the entire Genius Bus network. Faults such as device failures, shorts, or open wires are reported directly to the CPU for quick troubleshooting. CPU Offloading: Manages all I/O bus traffic independently, freeing up the main PLC CPU to focus on executing control logic, which enhances overall system performance. Easy Configuration: Configured using the Proficy Machine Edition software, allowing for straightforward setup of bus parameters and I/O devices. Technical Specifications Specification Value Product Family GE Series 90-70 Module Type Genius Bus Transmitter Module (BTM) Bus Protocol Genius I/O Number of Buses 1 Devices per Bus Up to 31 Genius I/O devices Data Rate 153.6 Kbaud (standard), 76.8 Kbaud, 38.4 Kbaud Power Consumption 1.0 Amp at +5V DC Operating Temperature 0°C to 60°C (32°F to 140°F) Slot Requirement 1 single slot in an IC697 PLC rack On-Board Diagnostics Module OK, Bus A OK, Bus B OK LEDs Applications The IC697BEM713 is ideal for industrial automation systems that require a reliable and extensive distributed I/O architecture. Common applications include: Manufacturing and Assembly Lines: Where sensors, actuators, and other field devices are spread across a large plant floor. Water/Wastewater Treatment: For monitoring and controlling pumps, valves, and instruments in remote locations. Power Generation and Distribution: To aggregate data from various subsystems within a power plant. Process Control: In industries like chemical, oil & gas, and pulp & paper where I/O points are geographically dispersed.

GE Fanuc IC697BEM713H - Genius Bus Transmitter Module Overview The GE Fanuc IC697BEM713 is a high-performance Bus Transmitter Module (BTM) designed for the Series 90-70 Programmable Logic Controller (PLC) platform. Its primary function is to serve as an interface controller for extending the PLC's I/O capabilities over the robust and deterministic Genius I/O bus. This module enables the central CPU to communicate with remote I/O blocks, creating a distributed and scalable control system architecture. It occupies a single slot in an IC697 PLC rack and acts as the master controller for one or more Genius I/O serial buses, managing data exchange with up to 31 remote I/O devices per bus. Key Features Genius I/O Bus Control: Acts as the bus controller for the proprietary GE Genius I/O network, known for its high-speed and reliable communication. Distributed I/O Capability: Allows for the connection of remote I/O blocks up to 7,500 feet (2,286 meters) from the PLC rack, reducing wiring costs and complexity in large-scale applications. High-Speed Data Transfer: Supports multiple baud rates, including 153.6K (standard), 76.8K, and 38.4K, providing flexibility in network design. Advanced Diagnostics: Provides extensive on-board diagnostics for the module itself and the entire Genius Bus network. Faults such as device failures, shorts, or open wires are reported directly to the CPU for quick troubleshooting. CPU Offloading: Manages all I/O bus traffic independently, freeing up the main PLC CPU to focus on executing control logic, which enhances overall system performance. Easy Configuration: Configured using the Proficy Machine Edition software, allowing for straightforward setup of bus parameters and I/O devices. Technical Specifications Specification Value Product Family GE Series 90-70 Module Type Genius Bus Transmitter Module (BTM) Bus Protocol Genius I/O Number of Buses 1 Devices per Bus Up to 31 Genius I/O devices Data Rate 153.6 Kbaud (standard), 76.8 Kbaud, 38.4 Kbaud Power Consumption 1.0 Amp at +5V DC Operating Temperature 0°C to 60°C (32°F to 140°F) Slot Requirement 1 single slot in an IC697 PLC rack On-Board Diagnostics Module OK, Bus A OK, Bus B OK LEDs Applications The IC697BEM713 is ideal for industrial automation systems that require a reliable and extensive distributed I/O architecture. Common applications include: Manufacturing and Assembly Lines: Where sensors, actuators, and other field devices are spread across a large plant floor. Water/Wastewater Treatment: For monitoring and controlling pumps, valves, and instruments in remote locations. Power Generation and Distribution: To aggregate data from various subsystems within a power plant. Process Control: In industries like chemical, oil & gas, and pulp & paper where I/O points are geographically dispersed.

GE Fanuc IC697BEM713J - Genius Bus Transmitter Module Overview The GE Fanuc IC697BEM713 is a high-performance Bus Transmitter Module (BTM) designed for the Series 90-70 Programmable Logic Controller (PLC) platform. Its primary function is to serve as an interface controller for extending the PLC's I/O capabilities over the robust and deterministic Genius I/O bus. This module enables the central CPU to communicate with remote I/O blocks, creating a distributed and scalable control system architecture. It occupies a single slot in an IC697 PLC rack and acts as the master controller for one or more Genius I/O serial buses, managing data exchange with up to 31 remote I/O devices per bus. Key Features Genius I/O Bus Control: Acts as the bus controller for the proprietary GE Genius I/O network, known for its high-speed and reliable communication. Distributed I/O Capability: Allows for the connection of remote I/O blocks up to 7,500 feet (2,286 meters) from the PLC rack, reducing wiring costs and complexity in large-scale applications. High-Speed Data Transfer: Supports multiple baud rates, including 153.6K (standard), 76.8K, and 38.4K, providing flexibility in network design. Advanced Diagnostics: Provides extensive on-board diagnostics for the module itself and the entire Genius Bus network. Faults such as device failures, shorts, or open wires are reported directly to the CPU for quick troubleshooting. CPU Offloading: Manages all I/O bus traffic independently, freeing up the main PLC CPU to focus on executing control logic, which enhances overall system performance. Easy Configuration: Configured using the Proficy Machine Edition software, allowing for straightforward setup of bus parameters and I/O devices. Technical Specifications Specification Value Product Family GE Series 90-70 Module Type Genius Bus Transmitter Module (BTM) Bus Protocol Genius I/O Number of Buses 1 Devices per Bus Up to 31 Genius I/O devices Data Rate 153.6 Kbaud (standard), 76.8 Kbaud, 38.4 Kbaud Power Consumption 1.0 Amp at +5V DC Operating Temperature 0°C to 60°C (32°F to 140°F) Slot Requirement 1 single slot in an IC697 PLC rack On-Board Diagnostics Module OK, Bus A OK, Bus B OK LEDs Applications The IC697BEM713 is ideal for industrial automation systems that require a reliable and extensive distributed I/O architecture. Common applications include: Manufacturing and Assembly Lines: Where sensors, actuators, and other field devices are spread across a large plant floor. Water/Wastewater Treatment: For monitoring and controlling pumps, valves, and instruments in remote locations. Power Generation and Distribution: To aggregate data from various subsystems within a power plant. Process Control: In industries like chemical, oil & gas, and pulp & paper where I/O points are geographically dispersed.

GE Fanuc IC697BEM731K Genius Bus Controller The GE Fanuc IC697BEM731 is a high-performance Genius Bus Controller (GBC) module designed for the Series 90-70 PLC platform. It functions as the master controller for a Genius I/O serial bus, enabling robust communication and control over distributed I/O devices. This module is engineered for demanding industrial environments requiring reliable, deterministic I/O scanning and diagnostics. Key Features & Specifications Module Type: Genius Bus Controller (GBC) Platform: GE Fanuc Series 90-70 Bus Protocol: Genius I/O Function: Acts as the bus master, controlling all communication and I/O scanning on the Genius bus. Device Support: Manages up to 31 Genius I/O devices (slaves) on a single bus network. Communication Rate: Standard 153.6 Kbaud. Also supports extended distance mode at 76.8 Kbaud. Diagnostics: Comprehensive onboard diagnostics reported to the CPU, with front-panel LEDs for Bus Status (BUS OK), Module Status (MOD OK), and Serial Port Activity (I/O ENBL). Configuration: Configured using GE's programming software (such as Proficy Machine Edition). All bus parameters and I/O device configurations are stored in the PLC's CPU. Form Factor: Single-slot VME-style module for the IC697 PLC rack. Connector: Standard 15-pin D-sub female connector for the Genius bus cable connection. Technical Details The IC697BEM731 offloads I/O scanning from the main PLC processor, providing deterministic updates and freeing up the CPU for logic execution. It cyclically polls each configured device (I/O blocks, remote drops, other PLCs) on the bus, exchanging discrete and analog I/O data. The module supports global data broadcasts and provides advanced fault reporting, allowing for quick identification of network or device issues. Power Consumption: 1.2 Amps at +5 VDC from the PLC backplane. Bus Length: Up to 7,500 feet (2,286 meters) at 153.6 Kbaud. Up to 11,000 feet (3,353 meters) at 76.8 Kbaud (extended mode). Data Exchange: Manages I/O data transfer between the bus devices and the PLC's %I, %Q, %AI, and %AQ memory tables. Applications This module is the ideal solution for integrating distributed I/O systems in complex automation environments. It is commonly used in applications requiring a robust and intelligent I/O network to connect remote panels, operator stations, and device-level blocks back to a central Series 90-70 controller. Connecting multiple remote I/O racks. Integrating smart devices like motor starters and drives. Building distributed control systems across a large plant floor. Upgrading or maintaining existing GE Fanuc control systems utilizing the Genius I/O protocol.

GE Fanuc IC697BEM731N Genius Bus Controller The GE Fanuc IC697BEM731 is a high-performance Genius Bus Controller (GBC) module designed for the Series 90-70 PLC platform. It functions as the master controller for a Genius I/O serial bus, enabling robust communication and control over distributed I/O devices. This module is engineered for demanding industrial environments requiring reliable, deterministic I/O scanning and diagnostics. Key Features & Specifications Module Type: Genius Bus Controller (GBC) Platform: GE Fanuc Series 90-70 Bus Protocol: Genius I/O Function: Acts as the bus master, controlling all communication and I/O scanning on the Genius bus. Device Support: Manages up to 31 Genius I/O devices (slaves) on a single bus network. Communication Rate: Standard 153.6 Kbaud. Also supports extended distance mode at 76.8 Kbaud. Diagnostics: Comprehensive onboard diagnostics reported to the CPU, with front-panel LEDs for Bus Status (BUS OK), Module Status (MOD OK), and Serial Port Activity (I/O ENBL). Configuration: Configured using GE's programming software (such as Proficy Machine Edition). All bus parameters and I/O device configurations are stored in the PLC's CPU. Form Factor: Single-slot VME-style module for the IC697 PLC rack. Connector: Standard 15-pin D-sub female connector for the Genius bus cable connection. Technical Details The IC697BEM731 offloads I/O scanning from the main PLC processor, providing deterministic updates and freeing up the CPU for logic execution. It cyclically polls each configured device (I/O blocks, remote drops, other PLCs) on the bus, exchanging discrete and analog I/O data. The module supports global data broadcasts and provides advanced fault reporting, allowing for quick identification of network or device issues. Power Consumption: 1.2 Amps at +5 VDC from the PLC backplane. Bus Length: Up to 7,500 feet (2,286 meters) at 153.6 Kbaud. Up to 11,000 feet (3,353 meters) at 76.8 Kbaud (extended mode). Data Exchange: Manages I/O data transfer between the bus devices and the PLC's %I, %Q, %AI, and %AQ memory tables. Applications This module is the ideal solution for integrating distributed I/O systems in complex automation environments. It is commonly used in applications requiring a robust and intelligent I/O network to connect remote panels, operator stations, and device-level blocks back to a central Series 90-70 controller. Connecting multiple remote I/O racks. Integrating smart devices like motor starters and drives. Building distributed control systems across a large plant floor. Upgrading or maintaining existing GE Fanuc control systems utilizing the Genius I/O protocol.

GE Fanuc IC697BEM731P Genius Bus Controller The GE Fanuc IC697BEM731 is a high-performance Genius Bus Controller (GBC) module designed for the Series 90-70 PLC platform. It functions as the master controller for a Genius I/O serial bus, enabling robust communication and control over distributed I/O devices. This module is engineered for demanding industrial environments requiring reliable, deterministic I/O scanning and diagnostics. Key Features & Specifications Module Type: Genius Bus Controller (GBC) Platform: GE Fanuc Series 90-70 Bus Protocol: Genius I/O Function: Acts as the bus master, controlling all communication and I/O scanning on the Genius bus. Device Support: Manages up to 31 Genius I/O devices (slaves) on a single bus network. Communication Rate: Standard 153.6 Kbaud. Also supports extended distance mode at 76.8 Kbaud. Diagnostics: Comprehensive onboard diagnostics reported to the CPU, with front-panel LEDs for Bus Status (BUS OK), Module Status (MOD OK), and Serial Port Activity (I/O ENBL). Configuration: Configured using GE's programming software (such as Proficy Machine Edition). All bus parameters and I/O device configurations are stored in the PLC's CPU. Form Factor: Single-slot VME-style module for the IC697 PLC rack. Connector: Standard 15-pin D-sub female connector for the Genius bus cable connection. Technical Details The IC697BEM731 offloads I/O scanning from the main PLC processor, providing deterministic updates and freeing up the CPU for logic execution. It cyclically polls each configured device (I/O blocks, remote drops, other PLCs) on the bus, exchanging discrete and analog I/O data. The module supports global data broadcasts and provides advanced fault reporting, allowing for quick identification of network or device issues. Power Consumption: 1.2 Amps at +5 VDC from the PLC backplane. Bus Length: Up to 7,500 feet (2,286 meters) at 153.6 Kbaud. Up to 11,000 feet (3,353 meters) at 76.8 Kbaud (extended mode). Data Exchange: Manages I/O data transfer between the bus devices and the PLC's %I, %Q, %AI, and %AQ memory tables. Applications This module is the ideal solution for integrating distributed I/O systems in complex automation environments. It is commonly used in applications requiring a robust and intelligent I/O network to connect remote panels, operator stations, and device-level blocks back to a central Series 90-70 controller. Connecting multiple remote I/O racks. Integrating smart devices like motor starters and drives. Building distributed control systems across a large plant floor. Upgrading or maintaining existing GE Fanuc control systems utilizing the Genius I/O protocol.

GE Fanuc IC697CMM711J Communication ComprocessorIC697CMM711J

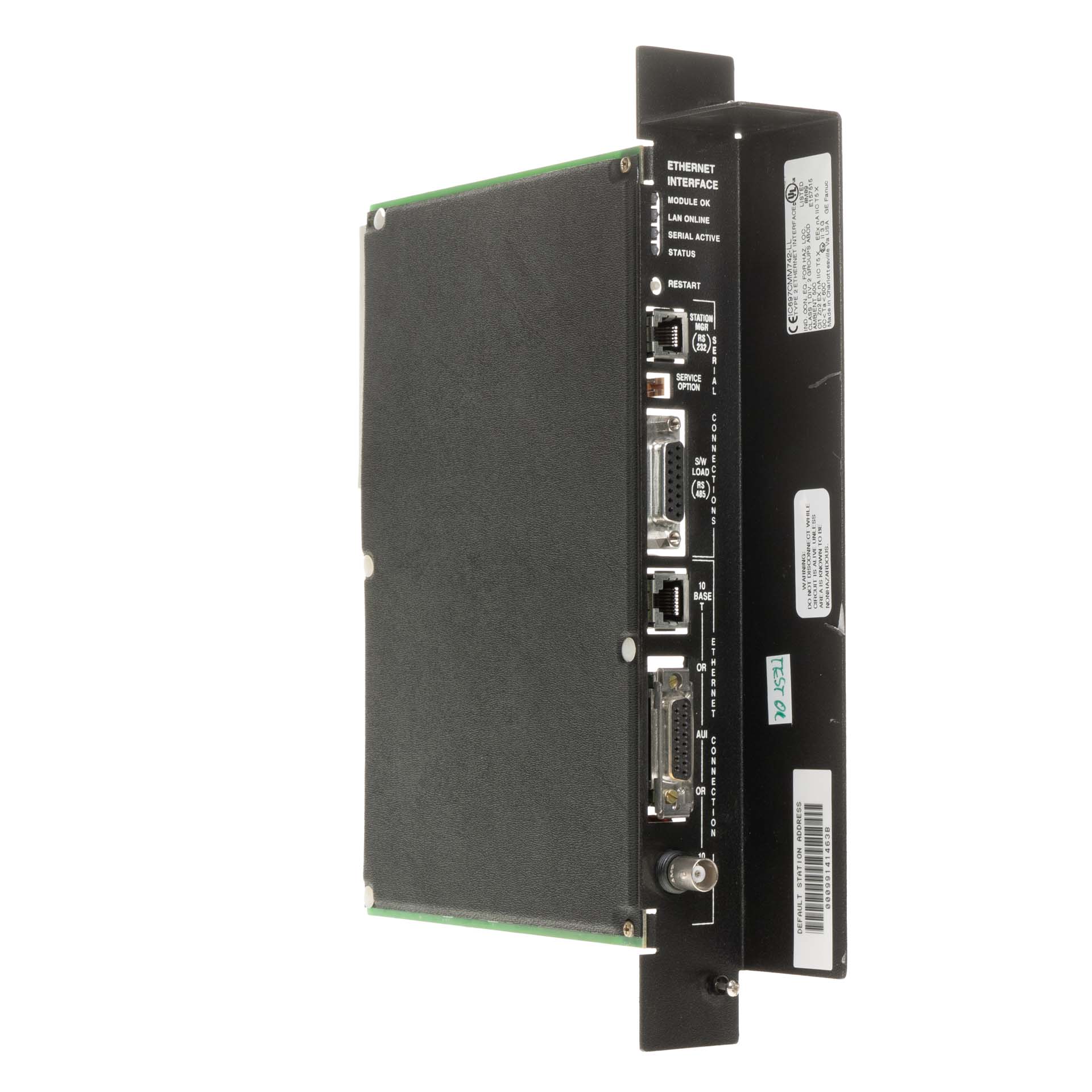

GE Fanuc IC697CMM742-LL IC697CMM742 Type 2 Ethernet InterfaceTested

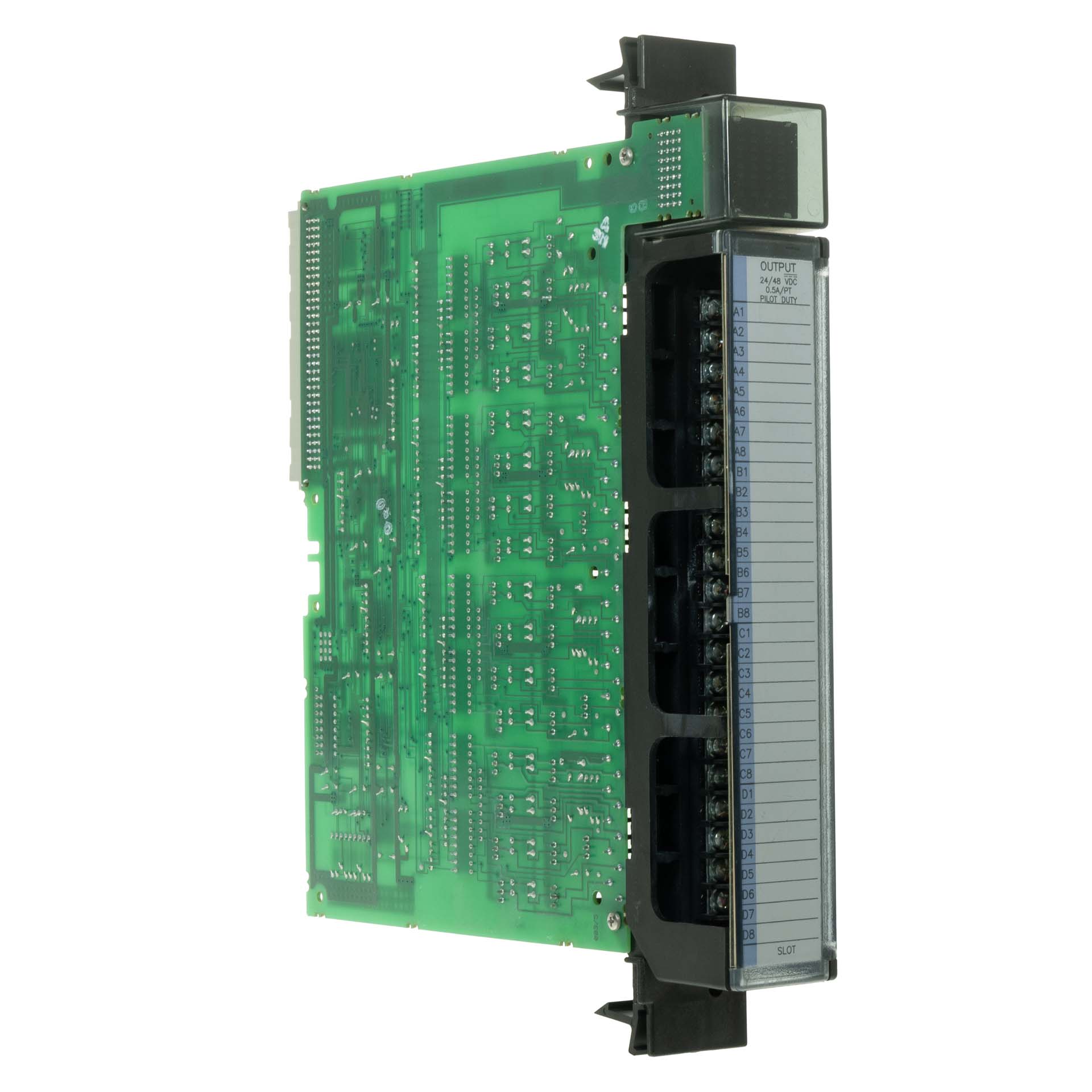

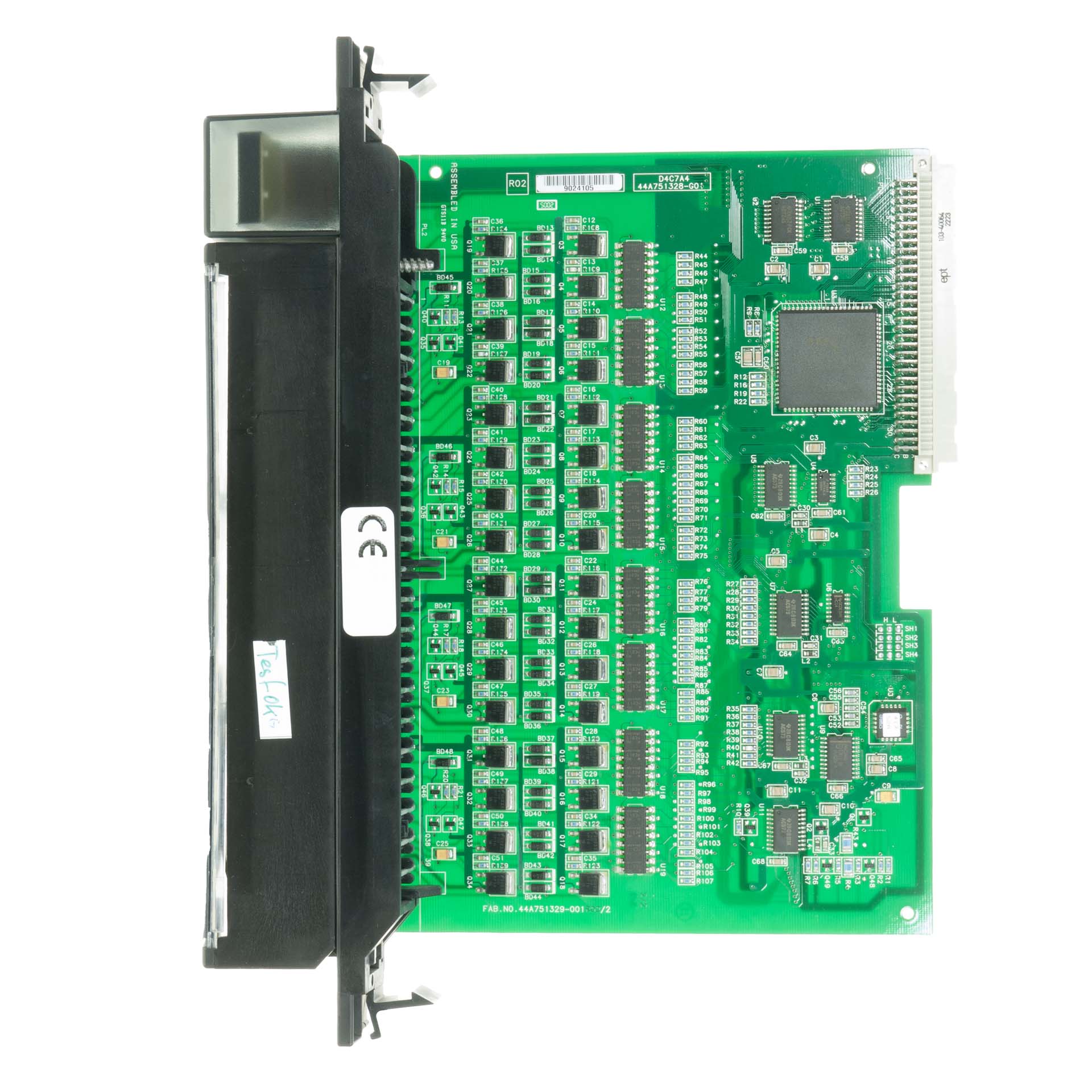

GE Fanuc IC697MDL750E IC697MDL750 Digital Out 24/48 VDC 0.5A/PT Module

GE Fanuc IC697MDL750G IC697MDL750 Digital Out 24/48 VDC 0.5A/PT Module

GE Fanuc IC754VSI12CTD-HH QuickPanel Model ES1221R HMItestedUsage marks and spots on foil, blue paint on plastic